The E4OD transmission is a pivotal component in many Ford vehicles, particularly those manufactured from the late 1980s through the mid-1990s. Known for its durability and robustness, it has been a reliable workhorse for both casual drivers and hardcore enthusiasts alike. However, the installation of an E4OD trans shift kit has prompted discussions among vehicle owners about potential side effects, particularly concerning high line pressure and error codes such as Code 625. This article delves into the contentious relationship between the shift kit and these technical issues, shedding light on nuances often overlooked.

The intricacies of the E4OD system lie in its hydraulic function. The transmission employs various hydraulically-controlled components to direct the flow of fluid within the system. A shift kit modifies these hydraulics, allowing for crisper shifts and improved performance. Yet, this modification can throw a wrench into the finely-tuned balance of the transmission’s operating parameters, potentially leading to complications.

Could the transformation initiated by a shift kit catalyze excessive line pressure? Indeed, it is a possibility. Line pressure is the force of transmission fluid within the system, which plays a critical role in determining the effectiveness of each shift. Enhanced shifts can inadvertently result in increased line pressure, as the modifications may require more fluid flow to achieve the desired actuation. Symptoms of elevated line pressure include harsh shifts, slipping, or even erratic behavior that may not conform to the owner’s driving expectations.

Understanding high line pressure is pivotal. When the pressure exceeds optimal levels, several repercussions can arise. One critical element affected is the solenoid function. Solenoids, small electromechanical devices, regulate fluid flow within the transmission. Should these components encounter unexpectedly high pressure, it can lead to premature wear and, ultimately, costly failures. Drivers may notice a change in how their vehicle operates, from less responsive shifting to a troubling transmission that struggles under duress.

Code 625, a diagnostic trouble code (DTC), signals a specific issue within the E4OD transmission system. It indicates an over-voltage condition in the transmission control module (TCM) or an issue related to the manual valve position sensor. The emergence of this code in the context of a newly installed shift kit brings forth an essential question: is the shift kit to blame? While it is tempting to correlate the two, one must approach the situation with analytical rigor.

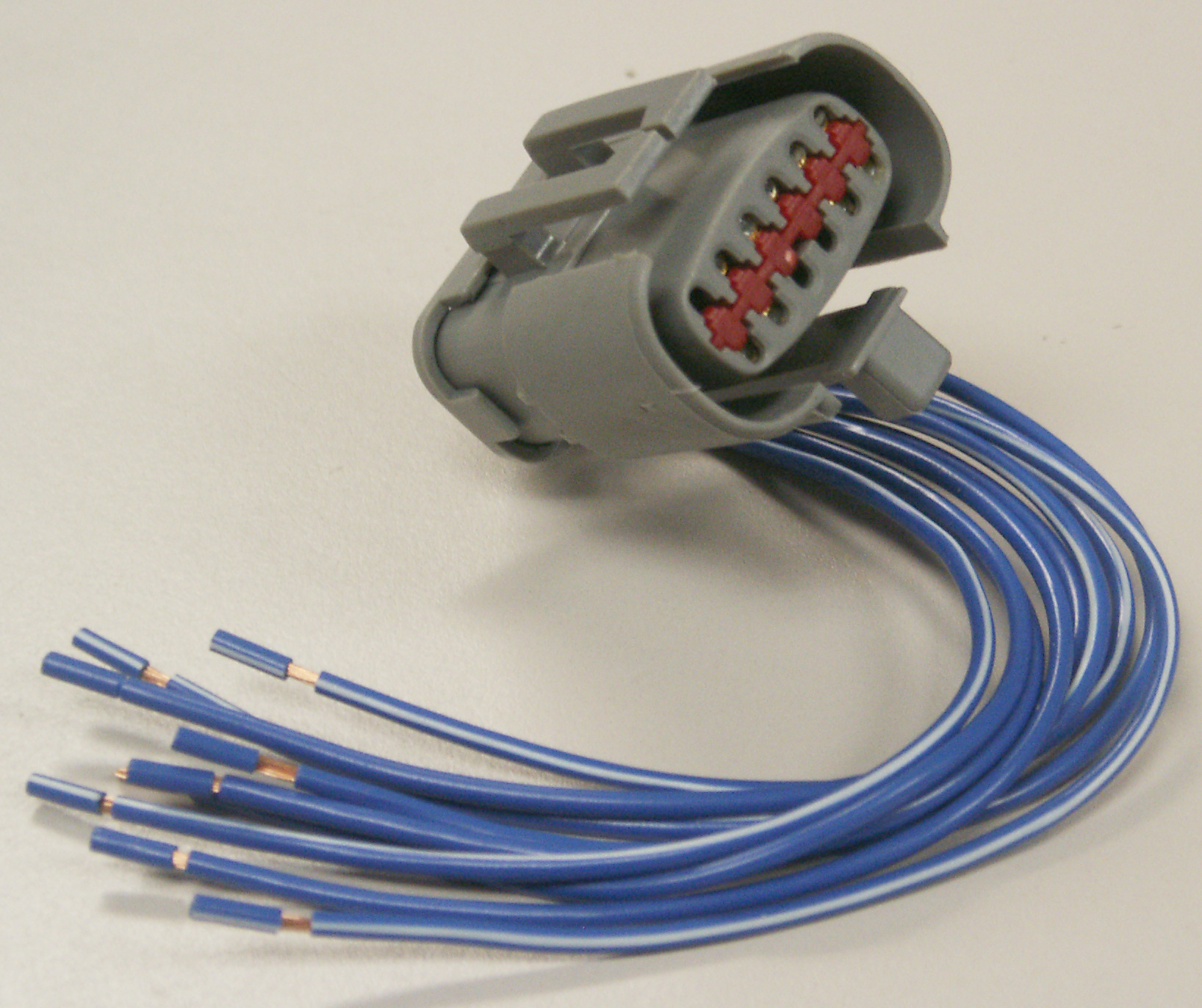

Upon installation, if a shift kit modifies the hydraulic circuits that engage the valves responsible for shifting, it may inadvertently lead to an over-activation of the system, thereby prompting the TCM to register an error. Furthermore, wiring issues or poor connections can compound the situation, especially in older vehicles, leading to a proliferation of erroneous codes. Therefore, while the shift kit could be a contributor, it is paramount to conduct a thorough review of the entire electrical and hydraulic system to ascertain the true cause of Code 625.

The balance between performance enhancement and mechanical integrity is crucial. Upgrading an E4OD with a shift kit may require additional enhancements elsewhere in the system. For instance, modified valve bodies and upgraded electronic controls can mitigate the risk of high line pressure, ensuring that the transmission remains finely balanced under various operating conditions. Driving habits and load conditions also play a significant role; aggressive acceleration and heavy towing can heighten stress on the transmission, magnifying any underlying issues exacerbated by the shift kit installation.

In some cases, enthusiasts choose to revert to the stock configuration of the transmission following a disappointing experience with a shift kit. This decision, however, can be double-edged. While returning to factory settings can alleviate symptoms like high line pressure and Code 625, it forsakes the performance gains that motivated the installation in the first place. Understanding one’s driving needs and the intended use of the vehicle becomes paramount in making this decision.

A preventative approach can offer peace of mind. Before installing a shift kit, prospective owners should engage in comprehensive research to understand the nuances of their specific transmission variant. Consulting with knowledgeable mechanics or transmission specialists can yield valuable insights into what modifications are necessary and what additional components may be required for a smooth integration.

Ultimately, while the E4OD trans shift kit can enhance performance and responsiveness, the potential for high line pressure and resulting diagnostic codes should not be taken lightly. Engaging in proactive maintenance, understanding the interplay of various components, and making informed decisions based on driving habits can ameliorate many of these concerns. The journey of enhancing a vehicle’s performance should always reflect a balance between aspiration and caution, ensuring that drivers enjoy the thrill of upgraded shifts without compromising reliability or incurring unnecessary diagnostic woes.