In the realm of modern technology, thermodynamics plays a pivotal role, especially within battery-operated devices. An ever-present concern is the phenomenon of thermal runaway, which can precipitate catastrophic failure. Understanding Marlin thermal runaway sensitivity is not merely a technical endeavor; it is a profound responsibility that transcends the mere act of calibration. It encapsulates an imperative to safeguard human lives, preserve resources, and maintain ecological integrity. This article delves into the intricacies of adjusting and preventing errors associated with thermal runaway in the Marlin firmware environment.

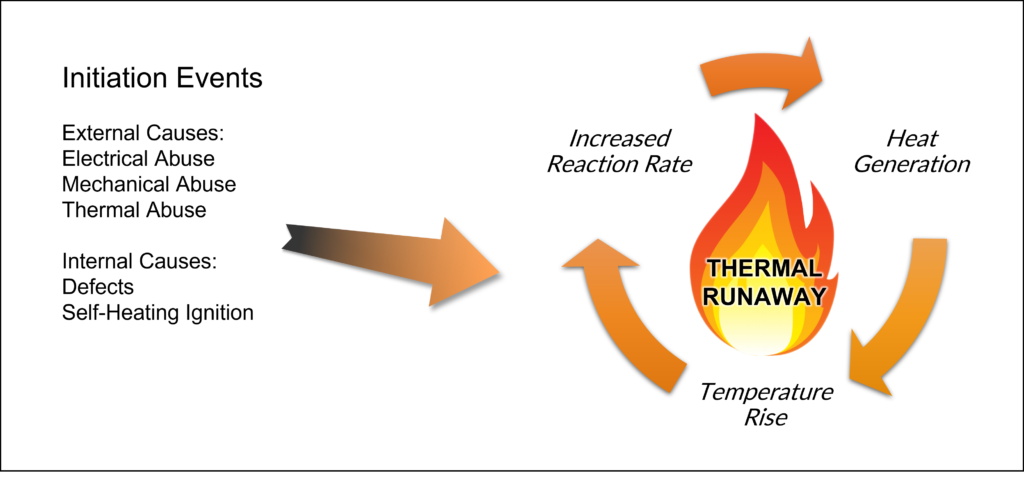

Thermal runaway occurs when a battery cell exceeds its thermal stability thresholds, leading to a self-reinforcing and often uncontrollable heat generation. This escalation can result in cell rupture, fire, or even explosions. The Marlin firmware, widely utilized in 3D printing, possesses components capable of mitigating such risks, but proper configuration is paramount. Key adjustments to Marlin’s thermal runaway sensitivity can help avert such dire consequences.

To grasp the significance of adjusting thermal runaway sensitivity, one must first understand the components at play. The primary actors include the thermistor, which gauges temperature, and the firmware configuration parameters that interpret these readings. Proficient manipulation of these elements is essential for ensuring not just functionality, but safety.

Begin with calibrating the thermistors. These devices convert temperature into electrical resistance and serve as a fundamental layer of protection against overheating. The specific thermistor model selected must align with the firmware configurations. Improper selection or incorrect configurations can hinder the thermistor’s efficacy, leading to erroneous temperature readings. Continuous monitoring and periodic recalibration will enhance their performance and ensure that they faithfully relay thermal data.

Once the thermistor is accurately configured, focus on the firmware settings. Two key parameters are critical: the thermal runaway protection thresholds and the temperature hysteresis. The former defines the parameters within which the system operates safely, while the latter offers a cushion against fluctuations that could otherwise trigger false alarms. Adjusting these thresholds requires a delicate balance. If the limits are set too stringently, they risk generating nuisance trips; too loose, and they become ineffective against true threats.

Specifically, the temperature threshold must account for the maximum operating temperatures of both the thermistor and the heating element. These values should be consulted in the manufacturer’s datasheets to ensure a thorough understanding of material properties and failure points. The recommended practice involves iterating on these values, performing test runs and carefully documenting performance to refine the settings progressively.

Another significant adjustment relates to the PID tuning for the heating elements. Proficient PID (Proportional, Integral, Derivative) parameters ensure that temperature is maintained within desired limits without excessive oscillation. Inadequate tuning can lead to overshoot conditions, whereby the temperature exceeds safe operational levels. Employing automated tuning routines available within the Marlin firmware can significantly enhance stability, but manual adjustments may be warranted in specific scenarios. The tuning process itself is an intricate dance between responsiveness and stability that warrants careful attention.

The next step toward error prevention lies in the implementation of preventative maintenance practices. Regular checks and maintenance of the entire thermal system contribute significantly to eliminating latent risks. This could encompass inspection of the wiring, ensuring thermal conductive materials remain untouched by contaminants, and confirming that cooling mechanisms, such as fans and thermal paste, function as designed. By preemptively addressing wear-and-tear, one can substantially mitigate the risk of thermal runaway incidents.

Beyond technical adjustments, fostering an organizational culture dedicated to education is vital. Engaging with the broader community through forums, tutorials, and collaborative projects provides insights that can yield improvements in safety protocols. Sharing experiences and learning from others can unveil innovative strategies for identifying and rectifying potential issues. Knowledge dissemination is paramount and contributes to widespread safety practices in the field.

Lastly, the integration of diagnostic tools can serve as an invaluable asset. Employing logging mechanisms that track thermal events enables operators to analyze trends and anticipate failures before they escalate. Such visibility into the system’s performance allows for data-driven adjustments and fosters a proactive approach to risk management. Furthermore, alert systems that notify users of impending thermal divergences can provide an additional safety net, enhancing operational resilience.

In conclusion, adjusting Marlin’s thermal runaway sensitivity is a multifaceted endeavor that requires a confluence of technical expertise, vigilant maintenance, community collaboration, and strategic foresight. It is more than merely tweaking settings; it is an essential practice that encapsulates the deeper meaning of responsibility within technological engagement. By understanding the intricacies of thermal dynamics and proactively addressing potential errors, stakeholders can forge a path toward a safer and more sustainable technological future.